INFOGRAPHIC

Better Living through Technology

From medical devices to biomedicine, see how emerging technologies are changing the future of health and medical design.

LEARN MORE >>

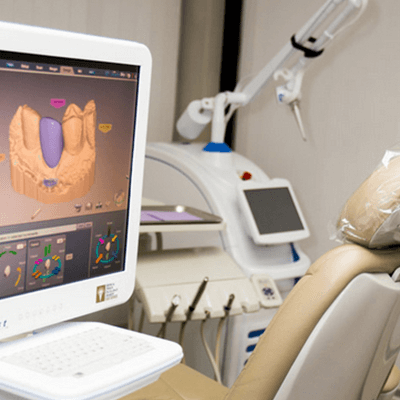

WHITEPAPER

Bringing Innovative Medical Products to Market Faster

This paper provides an overview of obstacles in the medical device industry, as well as the flexible design tools enabling medical innovation.

READ MORE >>

EBOOK

Simulating for Better Health

Read how validating medical product designs boosts innovation, improves quality and shortens time-to-market.

READ MORE >>