WHITEPAPER

Streamline Development of Industrial Machinery and Heavy Equipment

By taking advantage of a proven integrated

3D environment, you can design, validate, and produce higher quality, better-performing machines in shorter amounts of time—and at lower cost.

READ MORE >>

Analysis Guide for Machine Designers

This guide describes the key design performance issues facing machine designers and manufacturers, and identifies the benefits of using SOLIDWORKS analysis software in the product development cycle.

READ MORE >>

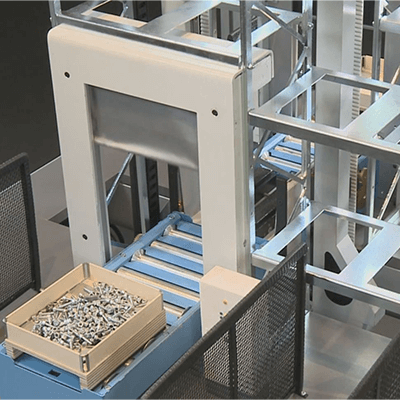

CASE STUDY

Thiele Technologies Eliminates Hours of Documentation Time

Thiele Technologies had the challenge of needing to provide customers with more effective tools for servicing and maintaining automated packaging machinery and equipment, as well as offering better support for customer training initiatives.

READ MORE >>