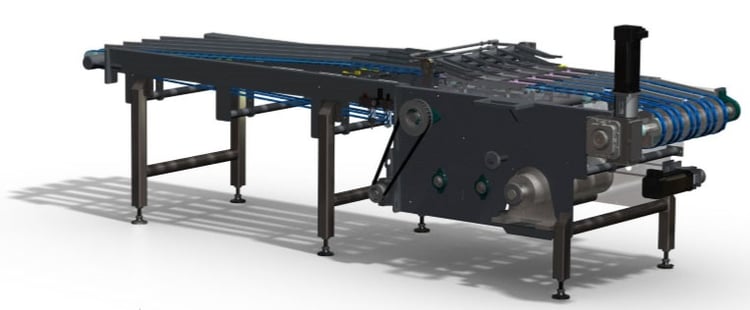

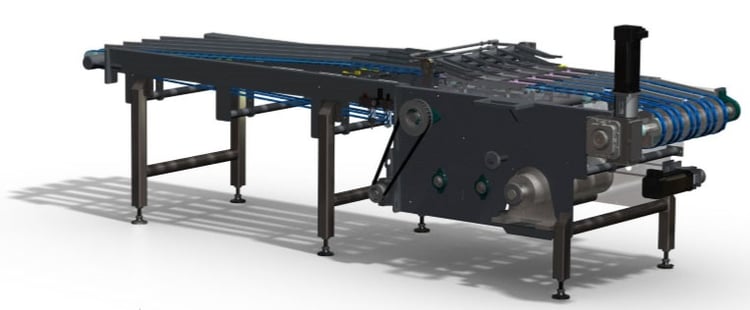

Equipment that processes food, beverages, dairy products, and pharmaceuticals is highly specialized. The tanks, conveyors, mixers, dispensers, and feeders comprising these systems must inherently be corrosion-resistant and sanitary, which requires the use of stainless steel and specialty alloys. When companies need this unique equipment, they often turn to Anderson Dahlen Inc., a leading provider of high-quality, custom metal fabrication services for more than 60 years.

Like many metal fabricators, Anderson Dahlen initially used 2D AutoCAD® tools for development. But the company eventually upgraded to SOLIDWORKS 3D CAD to more efficiently create designs ranging from sheet-metal parts and welded joints, to pressure vessels and complex assemblies. After seeing success with that initiative, CEO Thomas Knoll said that management decided to implement a product data management (PDM) system to achieve productivity gains on the manufacturing side similar to those experienced in design..

“We were using a server-based system of folders, which slowed down production,” says CAD Systems Manager Richard Trnka. “The old system lacked security and also had inadequate search capabilities, which limited our ability to leverage standard designs."

"For example, we use a lot of common parts, such as end plates and bearing mounts. Without a PDM system, we had instances when a designer would redesign an already existing part or create a part that didn’t function as well as one that someone else had already designed. With a PDM system, we hoped to minimize the potential for errors and automate workflows,” Trnka adds. “The ultimate goal was to address the causes of production delays—namely design errors, which require additional engineering, time, and rework—so we could increase throughput and save time and money in manufacturing.”

Anderson Dahlen evaluated the Autodesk Vault, DBWorks, and SOLIDWORKS PDM Professional packages before choosing SOLIDWORKS PDM Professional software, which the company selected because of its user-friendliness, utilization of an SQL database, full integration with SOLIDWORKS CAD software, and easy configuration.

“We wanted something that we could configure ourselves. If we needed to make a change, we could do so without having to hire a consultant,” Trnka stresses. “SOLIDWORKS PDM Professional has a graphical administrative tool and an open applications programming interface (API), which makes it easy to customize and adapt to our particular needs.”

Faster Sheet-Metal Fabrication

Following a phased PDM implementation that involved migrating 70,000 existing design files, Anderson Dahlen realized immediate benefits in the development of its systems, particularly in the design and fabrication of sheet-metal components and assemblies.

“Almost everything we do involves sheet metal,” Trnka points out. “It’s a lot quicker and more efficient to develop complex sheet-metal flats when you’re always working with the formed component in SOLIDWORKS. With PDM, we’ve connected the design with our laser-cutting system, which automates the process of producing flat patterns and creating code used to cut the parts.”

“We prefer to reuse designs whenever possible to reduce our design times and costs. With SOLIDWORKS PDM Professional’s search capability, it’s easy to find an existing design, using an attribute like material, size, or function,” Trnka continues.

“On average, a part search takes only about 1 to 2 seconds. Before we implemented PDM, we determined that our designers were spending an average of 40 minutes per day searching for parts. PDM capabilities—like search tools and automated workflows— help us reduce design time by 10 to 15 percent.”

Richard Trnka

CAD System Manager

Anderson Dahlen